Plane Mover #1 helps students reach for the sky

July 15, 2020, 3:46 am

Victor van der Merwe Local Journalism Initiative Reporter

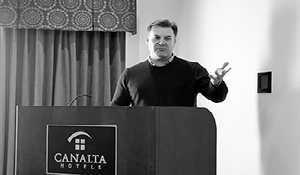

Moosomin Airport is the only place in the entire world where pilots can use the Plane Mover #1. This is because it was conceptualized, designed and built in the Industrial Arts Program provided by McNaughton High School Principal, Jeff St. Onge.

Plane Mover #1 is the result of St. Onge trying to find an easier way to get his plane out of the hanger.

“If you are a young guy, you can pull your plane out by yourself, but we’ve got a few (people) at the airport that can’t. I am one of the ones who can’t,” says St. Onge.

Necessity is the mother of invention maybe, but St. Onge also saw this as a learning opportunity for some of the students in his Industrial Arts Program.

“15 kids worked on this over three years, two at a time. If somebody wanted to learn welding I would teach them how to weld and then bring them out here to work on the mover,” Says St. Onge.

Two of the 15 that helped St. Onge were Alex Gmerek and Madison (Madi) Griemann.

Student who helped now aiming at PhD

Gmerek, who is currently doing an internship with Telesat Canada, has a bit of a history with St. Onge that starts long before the invention of the Plane Mover.

Gmerek knew early on that he was going to dedicate his professional life to aerospace engineering, and wanted to use his electives in high school to prepare himself for his post secondary life.

When St. Onge offered an electronics class, Gmerek signed up and asked if he could use the class to learn about robotics. St. Onge acquiesced. The year after that, Gmerek wanted to learn about computer programming and again St. Onge was there to help. In his final year of high school, Gmerek was tasked to help design the plane mover.

“It was a really good opportunity for me and I have since put that project on my resume. It looks great and I have had many conversations about it during interviews. I have also taken the knowledge I have gained and I have employed it heavily in my design courses. (The Plane Mover) was really beneficial for me and I am really glad I had that experience,” says Gmerek.

He responsible for taking his idea of a folding ramp to make the front wheel catch of the Plane Mover work better from idea to practical design. Since he had never done anything like this before, he appreciated St. Onge approach to the project.

“He was very patient with me. We sat down and figured out all the math together. Once we had the math planned out, it was a pretty simple process. I made a concept design out of wood, cardboard and string. By the time I graduated, the design was fully developed,” says Gmerek.

The robotics and computer programming courses he took in the years before the plane mover project didn’t translate directly into helping with the project, but the mathematics and troubleshooting skills did help him when it came time to design the folding ramp, and beyond.

“I’ve used both skills in my mechanical analyses and mechanical design courses since then and its been instrumental in helping me pass with relatively good grades.”

With the internship at Telesat Canada Gmerek has plenty of opportunity to keep on using the skills he required in the Industrial Arts Program.

“The project I am working on right now is a low earth orbiting satellite constellation. These satellites, instead of orbiting 36,000 km above the earth, orbit 1,000 km above the earth. The increase in speed between sending the signal up and then back down is on an order magnitude of 10 times. So you are looking at gigabits per second instead of megabits per second,”says Gemerek.

Once the internship is over, it is back to school for Gmerek where he will work towards getting his PhD before pursuing a career in research and development. Gmerek attributes some of his academic success to St. Onge for putting him on this path.

“If Mr. St. Onge didn’t tell me to go forward with the robotics course, I probably wouldn’t have had the drive to keep going,”says Gemerek.

Griemann receives her diploma in Innovative Manufacturing

Griemann, who has gone on to study Innovative Manufacturing at Saskatchewan Polytechnic joined the project after asking a simple question about a lathe.

“We were standing in front of a lathe and she (Madison) asked, “what’s this?” I said, well, that’s a lathe and I showed her and she was right into it and she did three classes with me and she went on to do computer aided manufacturing. She did very well, she was at the top of the class,” says St. Onge.

Griemann looks back at that moment with great fondness.

“I took lots of shop classes in high school with Mr. St. Onge. He had some little parts for me to make for the plane mover and I was excited to help,” says Griemann.

One of the parts that Griemann was responsible for machining, was the handles of the plane mover. St. Onge confesses that he would have just wrapped in duct tape, but since Griemann showed an interest in machining, the handles became much more intricate.

“I believe they are aluminum, a really fun metal to machine. They were machined on a manual lathe. They were roughed out to get the shape and then they would’ve been finished to size. To get the radius on the end of the handles, we ground a radius into a high speed steel cutter blank, this way we could use the new cutter to do both handles and get the same radius. The part was drilled on the lathe and then countersunk to leave room for the bolt head. The smaller diameter was then cut on an angle and then the bottom part was threaded. With this design, as the bolt was tightened, the bottoms part came up on an angle allowing for the handle to expand within the pipe and secure the handle in its spot,” says Griemann.

Griemann has just finished her diploma in Innovative Manufacturing and is qualified to do machining, welding and fabrication.

Gmerek and Griemann were only two of the 15 students who all benefitted in one way or another from the Industrial Arts Program. The idea was that the plane mover be used as a canvas for learning whatever they wanted to learn in the industrial arts. This would change the plane Mover in ways that St. Onge could not have imagined at the conception stages.

“I had a few kids who were interested electrical engineering. There is an onboard battery charger now. Its electric over hydraulic.”

Features that would not have been added are now a part of the machine because of what certain students wanted to learn.

“The part that I’m the proudest of is the kids that worked on it from my Industrial Arts Class,” says St. Onge.

Plane Mover #1 is at the Moosomin Airport and can be used by anyone who needs help moving their plane. Tweet