Golden Fortune officials speak at chamber meeting

February 25, 2018, 6:54 am

Kara Kinna

Meng Wu, assistant engineer, and Rong Liang, project geologist with the Canada Golden Fortune Potash Corporation spoke at the Moosomin Chamber of Commerce meeting last week about a planned solution potash mine that would be located 20 km south of Broadview.

Rong and Meng were invited to the meeting to share more about the project.

“We are really happy that we can have the Chamber of Commerce know more about our project and potential ways to help with our project,” said Meng, speaking to Chamber members.

How it got started

Meng went over some of the logistics of the project ,including where the company is at in the approval process.

Golden Fortune Potash Corp. was founded in 2014 in Saskatoon. Meng said the company has acquired two potash permits, one south of Grenfell and Broadview, and another north of Quill Lake, but their current focus is on the Broadview project.

He explained that the mine would be a solution mine.

“After construction, we will drill well pads, which are similar to oil and gas well pads, unto the ground and basically pump water into the potash bearing formation to mine the potash,” he said.

Meng said the company began drilling exploration wells in 2014 and, based on the core analysis, found an abundance of high grade potash in the area, which spurred them to start their environmental impact assessment in 2016.

“We have started to use all the base line data and also have started our modelling on the potential impact of this project,” he said.

“Now we are in the environmental impact assessment. We have submitted our technical proposal to the government and the government. We will submit an environmental impact statement with more details of the study to the ministry of environment.

“Now we are working on the impact statement and planning to submit it in the middle of 2018. We expect to wait for six months for the environmental approval. By the end of 2018 or early 2019 we will start our construction, but before that we will apply for our construction permit to allow us to break ground.

Project plans

“The construction is estimated to take two and a half years. During the two and a half years of construction we estimate that we will have average construction jobs of 600, and the peak number is 1,200 construction jobs.

“So we will need a lot of support from the local businesses, from Grenfell, Broadview, Kipling, and Moosomin.

“We plan to start our operations in 2021. We will be a one million tonne a year potash mine and there will be an estimated 155 permanent jobs working for the plant.”

Meng said water from the plant would be drawn from a deep aquifer—the Hatfield Aquifer—located north of Grenfell and southwest of Crooked Lake. “We have done a field water investigation of the water source last summer and we have confirmed there is sufficient water to support a one million tonne production mine,” he said.

He added that for the rail line, the company would build a spur line from the plant site to the CN line.

Solution Mine

Meng explained how the solution mine would work.

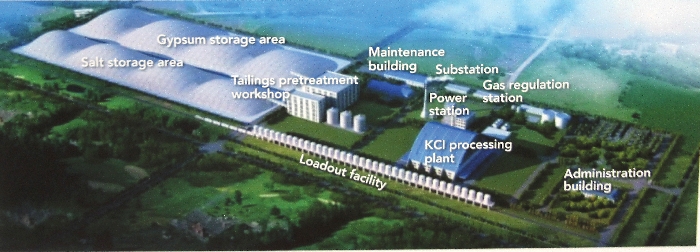

“It’s a lot different from the underground mines like Rocanville and Esterhazy,” he said. “Basically we will have water transported from the water source and the mine field into our plant. After the brine is pumped into our plant site, it goes to the KCL processing plant and the plant will separate salt and Calcium Sulfate, which is gypsum, in the plant, and also potash. And potash will be conveyed into the storage silos.”

He explained that the tailings would have a lot of moisture in them, so there would be little risk of salt blowing onto the ground.

“Production is only one million tonnes a year, which is way less than Rocanville and Esterhazy, which are five million tonnes a year, so there will be less impact on the area than the other mines,” he said.

“In the end of the production, the formation (underground) will be like a honeycomb or cheese, because potash only accounts for a quarter of the formation, so most of the salt will stay underground—we will only extract potash.

“There are two benefits of this method. First, we won’t have a large salt tailings at our plant because we have left the salt underground. Second is that we will have way less substance on the surface because the majority of the mineral is underground. There will only be potash extracted. From our preliminary analysis there will only be one to two meters of substance on the ground.”

Where the project is at now

Meng said the current focus of the company is on the environmental impact assessment. He said they have been collecting data since 2015 to examine the impacts of the project in the area, including information on air quality, acoustics, climate, hydrology, ground water, and local vegetation.

He added that this particular potash mine would use little water.

“We keep recirculating water into the cavern and reusing the water so the water consumption will be way less than any other solution mine or underground mine in Saskatchewan,” he said.

He said the company will be combining all of the data into their environmental impact statement and submitting it to the Minister of Environment for examination.

“Traffic is also very important for the local community because during construction we will be transporting heavy equipment, a lot of vehicles will be travelling to site,” he added. “Now we are trying to determining how much more traffic there will be during the construction and any impact for the local farmers. During construction we will start counting the traffic data and how many vehicles are coming in and how many are coming out. And before that we will work with the local RM to upgrade the gravel road.”

Meng said community engagement has also been a big part of the project.

“We started our community engagement since mid last year. We have had open houses in the surrounding towns,” he said.

“After we have all the environmental impact assessment results ready, we will present it to the local communities and hear more about their comments or any concerns about the study result. From our perspective we will keep engaging with the communities and also the RM, First Nation communities, and that is an ongoing process. It doesn’t end. After the environmental approval we will keep consulting the local communities to hear if there are any recommendations for the project after construction and into production.”

Meng added that, as part of their community contribution, the company would like to build a mineral spa in the area.

“In addition we are planning to build a not-for-profit mineral spa close to the project area,” he said. “We have not decided the location yet. It’s not for profit because we understand it may be a tourist attraction for the community if you have a mineral spa like the one in Moose Jaw, so it may help the local economy.

Questions and answers

After his presentation, Meng took questions from Chamber members.

Jim Davidson asked if the mine would draw any water from Pipestone Creek, or if any excess water would be put into Pipestone Creek.

“No, we won’t be drawing any water from Pipestone Creek,” said Meng. “Our water source will be from Hatfield Aquifer, it will be groundwater from just south of Crooked Lake. We have confirmed there is enough water for the project, so we won’t draw any water from Pipestone Creek. It will be recirculated. In the process there will be some water loss but we will recover most of the water and reinject it into the cavern, back into the mine.”

Bill Thorn asked if the gypsum byproduct would be processed locally or shipped elsewhere for processing.

“We will have a gypsum tailing area to store the gypsum, but we know that gypsum is a material to manufacture drywall, so we are looking at the potential uses of the gypsum tailings but we haven’t decided yet,” said Meng.

“Our gypsum will be high grade. For other gypsum mines in I think you need to process the gypsum to strip out some of the materials in it, but for ours it will be high quality so that would be really beneficial if we could have a gypsum plant to reuse it.”

Harry Meister asked if the salt and gypsum tailings would be covered or out in the open.

“There won’t be a dome for the tailing area but by the time the gypsum and salt will be transported to the tailings area, there will be some moisture in it so it won’t be blowing away as dust,” said Meng. “It will stay in the tailing area. And also our tailing area, we estimate the height will be way lower than the underground mines at Rocanville and Esterhazy. So there won’t be as much of an impact as the underground mines.”

Harry Meister asked if the wells for the mine would all be located in one spot.

“No, we are planning to have three well pads to support one million tonnes of production. In each well pad there will be around 14 wells drilled from that well pad,” said Meng.

Greg Nosterud asked who owns the company.

“Our stakeholders are mainly investors from mainline China, Hong Kong, some from Malaysia, and customers. It’s not publicly traded yet,” said Meng.

Bill Thorn asked where the potash would be sold.

“First our priority is for the local market, if there is demand locally in Saskatchewan it will be absolutely a priority because of the transportation and support for farmers locally,” said Meng. “Some of the product will be shipped around the globe. We have been talking to customers from India, from Malaysia, some from Brazil. We haven’t decided yet where our product will go because by the time of first production it will be in 2021. But basically it will be sold locally or to anywhere in the world that has a demand.”

Bill Thorn asked if the company has been in the potash mining before or if this is a first time venture and Meng said it was a first time venture.

Neil Russell asked if the mineral spa could be located in Moosomin. Meng said there was potential for the field office to be located in Moosomin.

“I believe by the time of production, we will have a training program, especially for young people, in the surrounding towns and communities. We would like to give back to people in the communities and Southeast Saskatchewan,” said Meng.

“For a field office, we will look at potential locations—the towns that are closer to our site, or a well established community like Moosomin. It is our first time coming to Moosomin. We were surprised that you have all these facilities, and I know that you have a hospital in Moosomin. We will report to management to see where we can locate our field office.”

Kevin Weedmark asked where the mine was in the permitting process.

“We are still working out the environmental statement,” said Meng. “We will submit it in June or July. After the environmental impact assessment is approved by the government, we will still have other permits to apply for, like the permit for the water source and permit for construction. So only after these permits are approved we can start the construction. We are still in the early stage of the project, but we are the fastest moving potash project in Saskatchewan in years.”

Dr. Wessel Roets asked if the medical aspect of the workers have been addressed by the company yet.

“We need some support in terms of the health system. Our priority for recruitment is for the people already living in the area,” said Meng. “We don’t wish to have 600 people coming to the site from out of province and have a huge pressure on the health care system. We will try to have the people hired locally as much as possible. It’s a way to give back to the people already here. It will also help stabilize the real estate and also the economic development.”

Harry Meister asked how thick the high grade potash ore body was when they cored in the mining area.

“Five meters of high grade potash,” said Meng, adding that that is much smaller than the underground mines.

“They are a lot thicker and shallower. That’s why they have chosen underground mining. In their depths the temperature is only 27-28 degrees celsius. This mine is deeper, and the formation temperature is 50 degrees which is not ideal for anybody to work underground.”

Larry Tomlinson asked how far out the solution mining process would go from the plant?

“In the beginning we will start to mine the area that is closest to the plant. At first it will be only one to two kilometres away from the plant. But as we keep mining we will move east,” said Meng.

Bill Thorn asked what the life expectancy of the mine would be.

“We are confident that we can have this mine operating for over 50 years, and that is only for the current designated mining area, and after that we can mine the area that is already in the permit area but not in our current mining plan. So our mine will be a long term neighbor,” said Meng.

Kevin Weedmark asked where they would source their permanent employees from.

“For some specialized personnel, we will probably have to find them from other cities in Saskatchewan or abroad but we will mostly try to utilize the local people,” said Meng. “We have heard from the other mines that if you bring someone from, say, Calgary, they may only work for your mine for two or three years and then find a better job, or just leave, because they are not born and raised here. But for us, from the very beginning, we’d like to implement a training program and train a local workforce.”