Nutrien Rocanville receives Technology Fund grant for sustainable mining initiative

December 1, 2025, 2:14 pm

Ashley Bochek

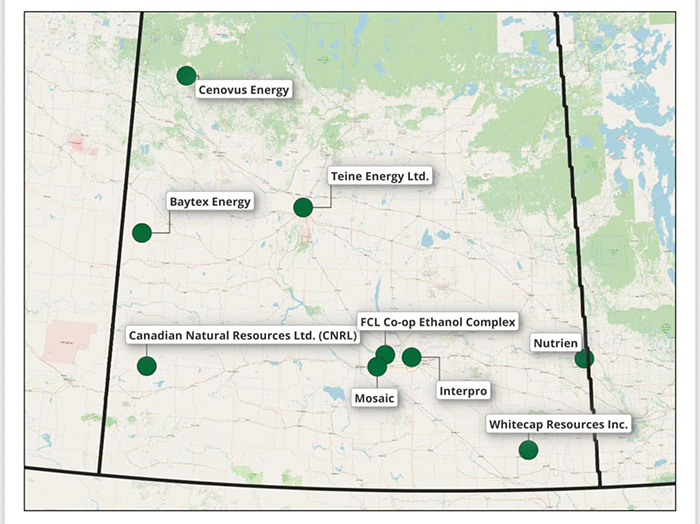

Nutrien Rocanville was recently awarded $1.2 million from the provincial government for their new innovative technology for more efficient and sustainable mining.

The Saskatchewan Technology Fund is a provincial fund that helps support industrial projects in reducing emissions and drive sustainable growth.

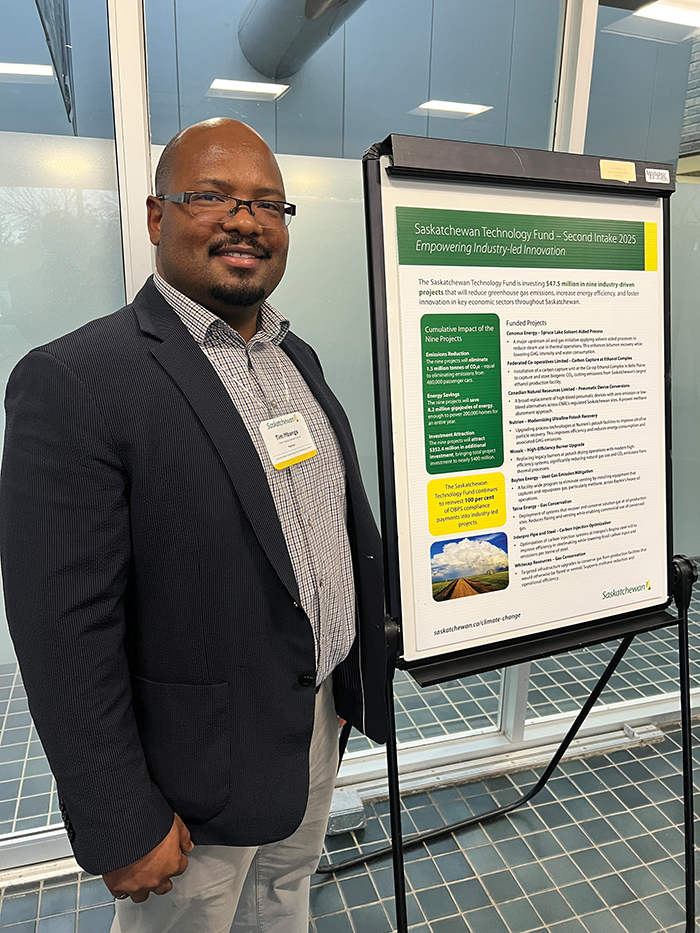

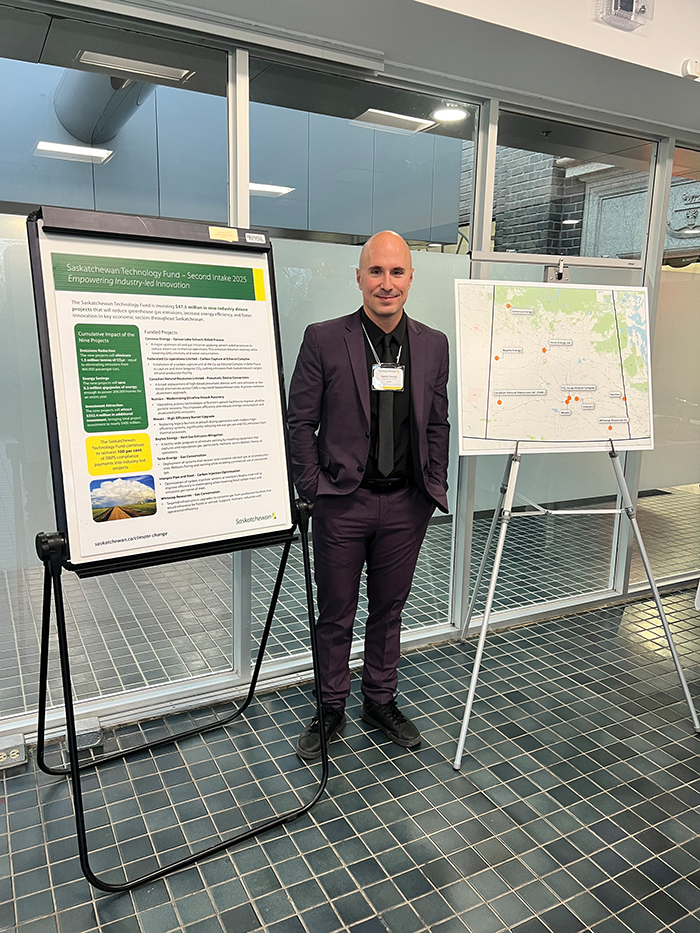

Justin Young and Tim Mbanga of Nutrien Rocanville explain their new innovative project chosen among nine other projects funded by the Saskatchewan Technology Fund.

Nutrien Rocanville is the largest potash producer in the country and is continuing building opportunities for long term growth.

“We’re actively exploring opportunities across our potash network,” Young explained. “With the global population steadily rising and the amount of arable land for crop production shrinking, we face a critical challenge, ensuring we can increase crop yields to meet growing food demand. That’s why it’s essential we continue to expand our production capabilities—so we can help feed the future and support global food security.”

Striving toward efficiency

Tim Mbanga, Mill Maintenance Superintendent at Nutrien Rocanville, highlights the company’s commitment to operational efficiency and sustainability.

“The most important thing is efficient production of resources—maximizing recoveries, reducing waste, and minimizing emissions,” he explains. This approach aligns with Nutrien’s broader corporate strategy to optimize its three core segments, Upstream (manufacturing facilities, for example, Mines), midstream (distribution and logistics), and downstream (agricultural customer/ end-user support).

“Unlike traditional fertilizer producers, Nutrien offers an integrated model that spans from mining and manufacturing to customer engagement. This includes soil testing, pH control, and tailored fertilizer recommendations,” Mbanga explains, as game changer services within the industry.

“Before Nutrien was formed in 2018, PotashCorp focused solely on fertilizer production with limited distribution. Today, Nutrien provides a complete support chain from manufacturing to the farmgate, and no competitor offers this level of integration.”

Saskatchewan Technology Fund

Mbanga explains Nutrien’s efforts to innovate through provincial programs.

“Recently, Nutrien Rocanville applied for the provincial Technology Fund, initiated by corporate outreach encouraging project submissions. The Fund was aimed at supporting industry-driven technology, innovation and improvement projects that mitigate, sequester or capture greenhouse gas (GHG) emissions. I saw that as an opportunity for the Ultrafines Recovery Project, so I talked to Justin Young, explained to him about the funding and said to him, ‘I have a project in mind and I would like to apply’ and he said ‘If you have all the information, let’s put our best foot forward and get that application in!’, and we did exactly that.”

Collaborative process

Mbanga says the project application was a collaborative process among himself and coworkers.

“I worked with site leadership, Rocanville site and corporate resources to prepare and submit a proposal aimed at leveraging this funding opportunity.

This initiative reflects Nutrien’s ongoing drive to leverage technology and funding opportunities to enhance efficiency and sustainability across its operations.”

Young adds, “This funding that we received from the provincial government will be going toward Tim’s idea on the Ultrafine potash recovery project. We are in the early design stages of the project and this funding will help push that along. We received $1.2 million from the Saskatchewan Technology Fund. We are currently also working with the federal government on another grant that could add a few more dollars to the pot for this specific project. Hopefully, if we do get both grants it should cover about 10 per cent of the total project cost. The rest would be covered by our capital sustaining budget, and we currently have that within our capital plan, and we are expecting this project will be online in 2027.”

Nutrien Rocanville has secured additional financial support for its emissions-reduction initiative, with conditional approval from both provincial and federal programs. Alongside $1.2 million from the Saskatchewan Technology Fund, the site has secured $2 million through the federal Green Industrial Facilities and Manufacturing Program (GIFMP), totaling government contributions to approximately $3.2 million—about 10 per cent of the project’s overall cost.

“This level of support is significant,” says Mbanga “The government recognizes the role we can play in reducing emissions and mitigating global warming.

Their financial backing is critical because despite Nutrien’s size, we compete internally for capital across numerous projects—terminals, rail, other mines, and more. With over 20,000 employees and multiple priorities, having this external support gives us the momentum we need.”

The funding highlights Nutrien’s commitment to sustainability and innovation, enabling the company to accelerate projects that deliver measurable environmental benefits while maintaining operational efficiency.

The project

Nutrien Rocanville is taking a big step toward sustainability and operational efficiency with an innovative project initiated by Mill Maintenance Superintendent Tim Mbanga.

The initiative focuses on upgrading unit processes in the site’s older mill, which was built in the late 1960s and is nearing the end of its lifecycle.

“The question was, what would it take to restore this unit operation and extend its life by another 30 to 40 years?” Mbanga explains.

The crystallization process is the most challenging and is traditionally used to convert fine potash particles into larger crystals suitable for sale. This process is energy-intensive, requiring temperatures up to 100°C. However, Nutrien’s newer mill, commissioned in 2016, introduced advanced drying technology that eliminates the need for crystallization. “We proved that we can process fine potash without crystallizing it, which improves safety and reduces energy consumption,” says Mbanga.

“Rather than installing new dryers in the older mill—a costly option—the team designed a solution to leverage existing capacity in the newer facility. “We decided to send ultra fine product directly to the new mill for drying. This technology was groundbreaking when implemented in 2012—the first and largest of its kind in the potash industry—and we’ve proven it works,” Mbanga notes.

The project is expected to significantly reduce greenhouse gas emissions and energy use — one of the key reasons it was selected among nine other projects by the Saskatchewan Technology Fund. “The emissions reduction is substantial. From an energy standpoint, this project is about creating technology that minimizes or eliminates unnecessary consumption,” Mbanga emphasizes.

Mbanga designed the ultrafine recovery system, completing all initial calculations and leading the application process for funding. “I plan to be involved from start to finish on this project—overseeing detailed design, execution, commissioning, and ensuring the system runs as intended,” he says.

Impact on mine

The new project at Nutrien Rocanville is designed to make future operations more sustainable by improving efficiency and reducing environmental impact.

“The main thing is sustainable production—that’s the key,” says Tim Mbanga, “Currently, the recovery process for ultrafines is one of the most challenging and energy-intensive steps in our operation. By moving away from this high-energy intensive process and adopting a more efficient technology, we can significantly reduce emissions and natural gas consumption.”

The initiative will not only lower greenhouse gas emissions but also improve overall yield and recovery of ultrafine potash products. “This technology allows us to optimize recovery while minimizing energy use, which is a win for both efficiency and sustainability,” Mbanga explains.

Young explains the new technology will allow for higher recovery, “If we didn’t proceed with this project, all of this ultrafine material would end up on the tailings pile and not be recovered. So, this potash would then ultimately become waste.”

Excitement for new project

Mbanga and Young say they’re excited for the benefits the new project will bring to Nutrien.

“It will be nice to see it,” Mbanga said. “It took about a year with the government application. There was a lot of back-and-forth. The approval of the project marks a check box, but now I’d like to make sure that it gets through to construction and make it happen.”

“By dealing with this aging crystallizer asset in mill one and completely removing it from the process there is a huge safety benefit that I am excited about,” said Young. “It was very expensive to run the crystallizer in mill one because of the high temperatures involved and the amount of gas you’re consuming, so moving that cost from the balance sheet also has me excited.

Then lastly, improving our recovery going forward to ensure that we are maximizing what we are getting out of the ore has me thrilled. Those would be my three biggest improvements that this new project gives us.

“It is helping us out with safety, production cost, and our production efficiency.”

Largest potash producer

Young says Nutrien is the world’s largest potash producer and is continuing to grow.

“If you were to look across the globe based on our potash network, Nutrien is the world’s largest potash producer and Nutrien Rocanville is one of the world’s largest potash operations.

“We have seen steady growth for multiple years and looking into the future, continue to see steady growth for global demand.

“I believe that probably played into us being chosen among the other nine projects for this funding from the Technology Fund,” he adds.

“I see that Mosaic also received funding with a very different project, but something similar in the space getting funded—I think it’s great that the Saskatchewan government recognizes the impact potash has, not only in the province, but around the world, and recognizing companies like ours and Mosaic’s. That is very important.”

Industry’s importance to province

Nutrien Rocanville is focused on shaping the future of mining with a strong commitment to sustainability and responsible resource development. “The main goal is to produce potash as ethically and efficiently as possible,” says Mbanga, Mill Maintenance Superintendent. “The greenhouse effect and global warming are real—we’re seeing plus-degree temperatures in late November here in Saskatchewan, which is unusual. That reality drives our focus on reducing emissions.”

Mbanga emphasizes that Saskatchewan has a unique opportunity to lead by example. “The province holds 27 of Canada’s 34 critical minerals, and potash is the largest among them. Saskatchewan has the world’s largest potash deposits, and we want customers and investors to know that our product is produced responsibly. If we can demonstrate that sustainable mining works here, it’s a win for the province, the country, and future generations.”

Mbanga adds that government support for these initiatives is motivating, “When you see the province and federal government backing projects like this, it speaks volumes about the shared commitment to reducing environmental impact and ensuring long-term sustainability.”

Young adds, “I do think it is valuable for our government to ensure that we are continuing to fund projects like this one that is essentially reducing our carbon footprint.”

End goal

The ultrafine recovery project at Nutrien Rocanville has been in development for several years, with a clear focus on efficiency and cost reduction. “We’ve worked on this project for quite a few years and wanted to minimize the capital requirement significantly,” says Mbanga. “Refurbishing the entire circuit would cost over $100 million, but with this approach, we can achieve the same goal for less Tweet